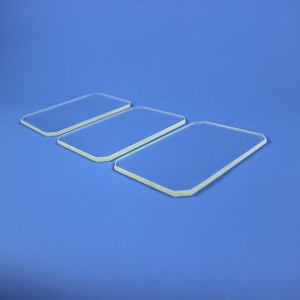

Halbeegga Taper Ground Quartz Isku-dhafka Qurxinta

Sagxadaha quraarad ee barafaysan, saxan-dhulku waxay sameeyaan shaabad wanaagsan marka si habboon loo subkay iyo Qalabka Shaybaadhka

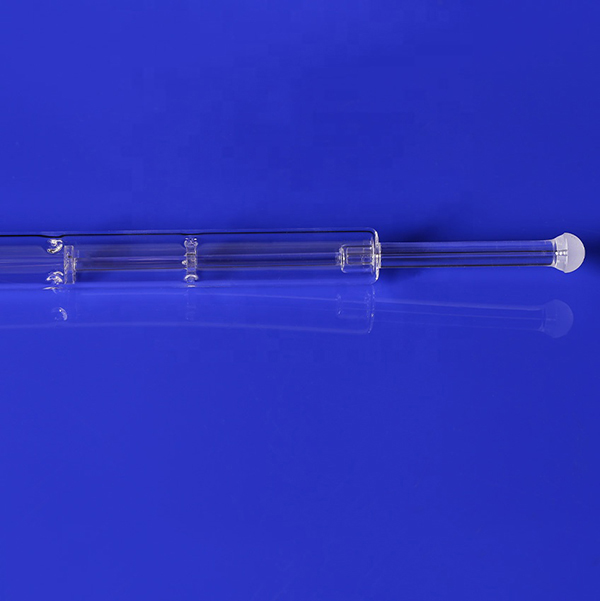

Kubadaha adag ee Quartz Machined waxaa loo isticmaalaa qalab u baahan kala-goysyada leh xoog dheeri ah, adkeysi iyo joogteynta cabbirka.

Maaddaama kala-goys kastaa leeyahay taper caadiga ah, labada qaybood ee isku midka ah ee dhexroorka dibadda ah ayaa isku qabsan kara midba midka kale.

Cabbirka

Cabbirka wadajirka galaaska waxaa lagu sifeeyaa tiro xx/yy ah.

XX waxay tilmaamaysaa dhexroorka gudaha ee isku-xidhka dibadda, ama dhexroorka dibadda ee wadajirka gudaha, yy wuxuu muujinayaa dhererka.

Cabbirrada caadiga ah ee caadiga ah waa sida soo socota, 14/20, 19/22, 24/40

cabbirada kale sidoo kale waa la beddeli karaa

Habaynta qaababka kale

foorarsan

Ubax

Doming

Tubbooyinka

Dhammaadka xiritaanka

alxanka

Faa'iidooyinka Alaabta

adkeysiga heerkulka sare

Iskudar hoose oo balaadhinta kulaylka

Iska caabbinta shoogga kulaylka wanaagsan

Dabool koronto oo heer sare ah

Nadiifinta kiimikada sare

Heerkulka ugu badan ee hawlgalka ee 1100°C (si joogto ah), ama 1300°C (waqti gaaban)

Alaabta la muujiyay

Codsiyada

Qalabka Shaybaadhka

Qalabka kiimikada

Kiimikada iyo dawooyinka

Sifada Quartz

| Cufnaanta | 2.2g/cm3 |

| Xoog xajin | 50Mpa |

| Iska caabbinta is-beddelka | 60-70 |

| Xoog cadaadis leh | 80 ~ 1000 |

| Iska caabbinta saamaynta | 1.08Kg.cm/cm2 |

| Mohs′adness | 5.5-6.5 |

| Iska caabbinta korantada ee hoos u dhaca heerkulka ugu hooseeya | 1018 (200C)Ω.cm |

| Dielectric joogto ah oo hoos yimaada heerkulka caadiga ah (ε) | 3.7 (Hz 0 ~ 106) |

| Awoodda koronto ee heerkulka caadiga ah | 250-400Kv/cm |

Waqtiga Hogaaminta

Qaybaha saamiyada, waxaanu ku soo rari doonaa hal todobaad gudaheed. Wixii qaybo gaar ah, fadlan nala soo xiriir wixii macluumaad dheeraad ah. Haddii aad u baahan tahay degdeg, waxaanu kuu diyaarin doonaa mudnaanta.